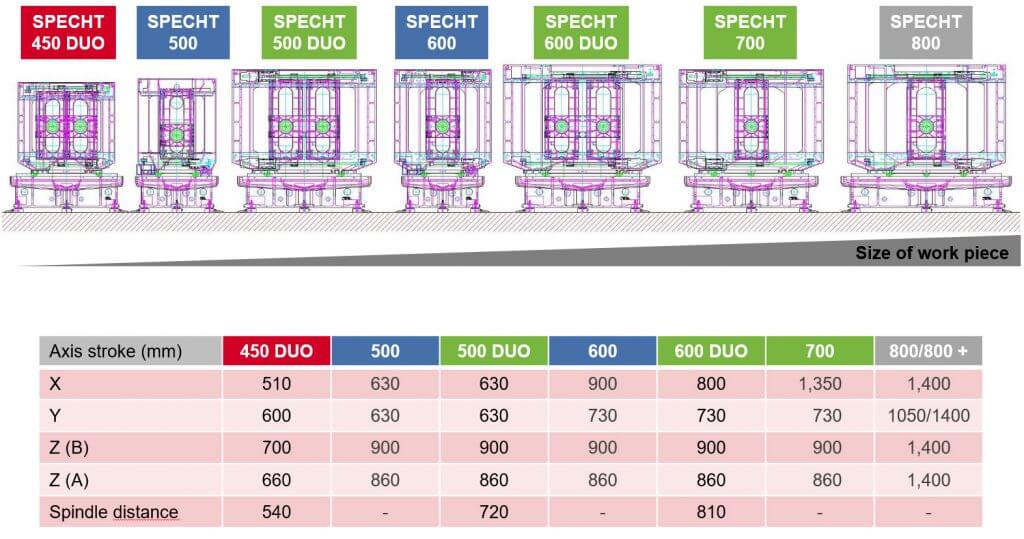

The MAG SPECHT® machine program – Maximum stability through optimal axis arrangement The intelligent axis layout with two axes (X/Y) in the tool and up to three possible axes (Z/A/B) in the workpiece movement ensure maximum stability. The jig boring machine principle stands for the highest accuracy and allows the use of longer tools. The optimum axis layout also ensures the shortest positioning times and minimum unproductive travel. Cost savings arise from the compact design and the resulting minimal space requirements.

The MAG SPECHT® CNC machining centers are ideal as interlinked multi-machine systems. They can also be used as a stand-alone machine and in manufacturing cells. The convincing feature of these single-spindle CNC systems is their modular structure, which provides maximum flexibility and makes them individually configurable. This enables the main spindle to be chosen from a selection of motor and gear spindles. A ball screw or linear motor drive can be used for the axis drive. MAG SPECHT CNC systems can therefore be ideally adapted to the respective machining requirements and surrounding infrastructure.

The SPECHT® innovations – Highest continuous accuracy thanks to intelligent technology In order to fully benefit from the productivity advantages of dual spindle machines SPECHT® DUO units are equipped with a unique compensation system. With the measurement compensation in all linear axes, both spindles of the DUO-machine can be positioned with micrometer accuracy to one another. In conjunction with the temperature compensation in the machine bed, on the axes, in the fixture and in the workpiece, constant and sustained accuracy is maintained. The result: “First Part = Good Part”, without machine warm-up.