|

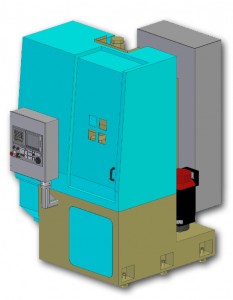

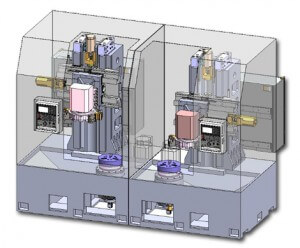

At SMS, our engineering and manufacturing groups utilize advanced CAD/CAM/CAE, as well as Solid Edge 3-D modeling and AutoCAD systems to produce quality design concepts that meet and/or exceed your needs.

To ensure committed customer deliveries, our Project Management Team monitors and directs all phases of the project, in an effort to maintain and manage the critical path timing of each project. This project management model tracks material and labor flow through our engineering, purchasing, machining, and assembly functions. Customer acceptance criteria is determined at the initial stages of each project, and managed appropriately to meet that goal. Customer satisfaction is the ultimate factor that SMS strives towards, with each project.

SMS has more than 100,000 square feet in its high-tech Saginaw Michigan facility. We have the engineering, manufacturing, and assembly capability to produce fully processed / turn-key manufacturing systems, and standard CNC Machining Systems of the highest quality.

SMS markets through directs sales and a worldwide network of sales representatives and distributors. We serve a wide range of industries including; automotive, truck and off-road vehicles, aerospace, aircraft, home appliance, construction, mining, ordnance, and oil.

Our machining systems do not travel alone. SMS engineers and technicians oversee the installation and start-up. And we service the machine systems we sell, providing the replacement parts, service and engineering support to keep our customers’ business operating uptime, at its maximum.

|

|

|